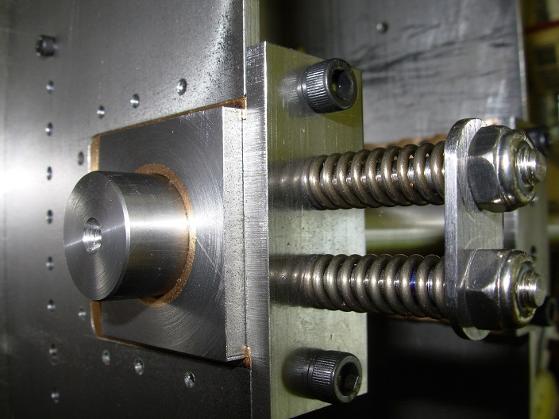

Axle Blocks

Here's a few photos of the machining of the axle blocks.

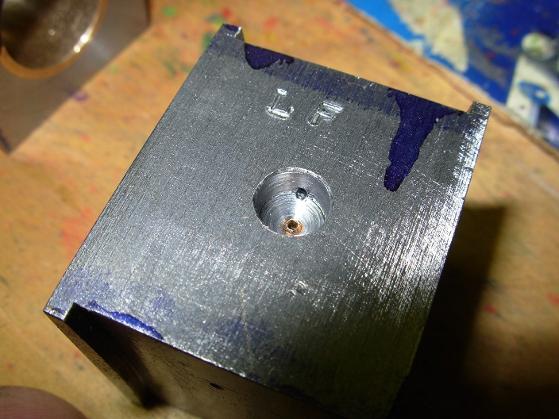

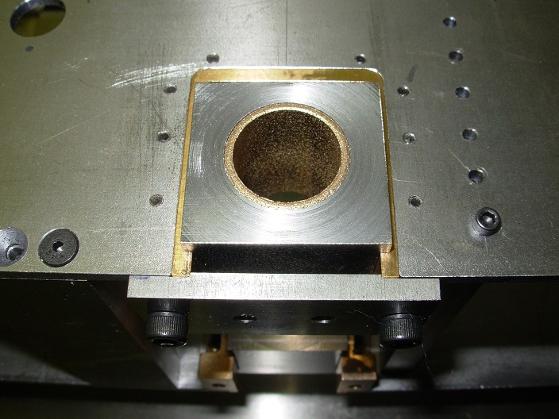

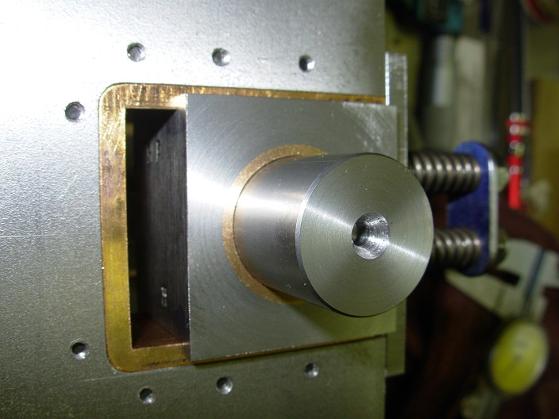

Each block was drilled, bored and reamed to final size for a press fit of a bronze bearing sleeve.

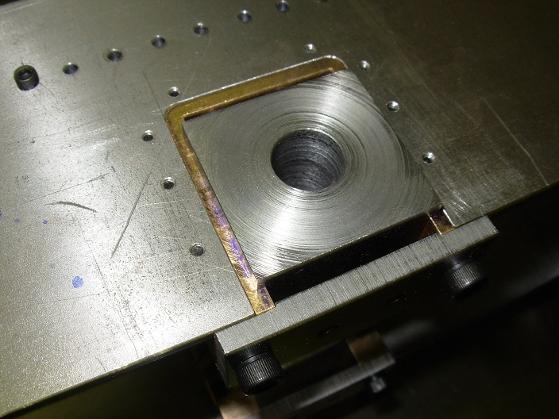

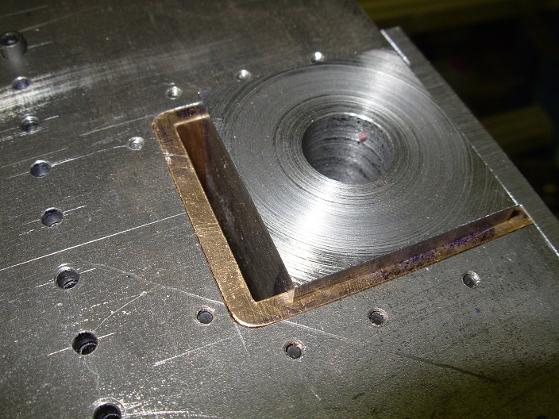

The flanges of the axle boxes must have a slight radius so each box can move up and down in the horn block independent of the other block on the same axle.

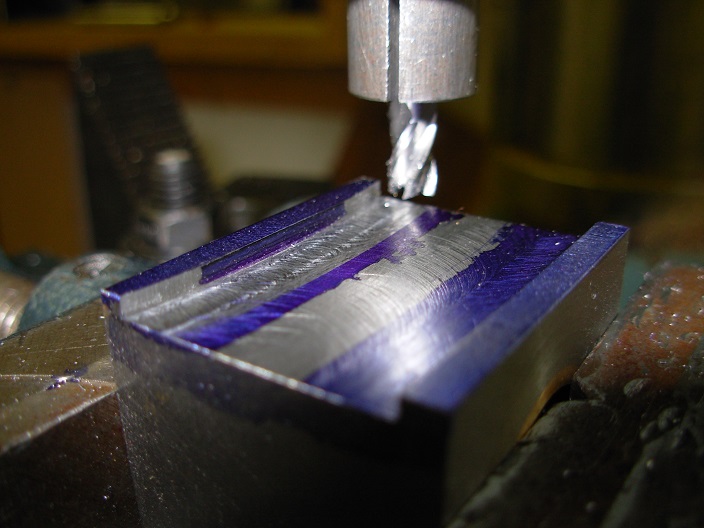

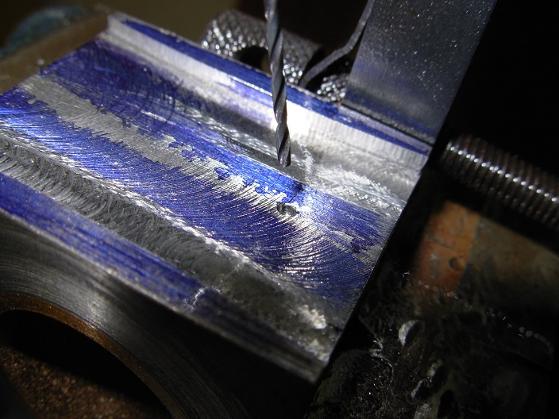

Each blocks is drilled for oil passages. One straight down to the axle, and one to each side to lubricate between the block and the horn block.

A "V" block jig was made up to machine each axle block. Each block was placed into the jig such that it would be in the same relationship in reference to the frame.

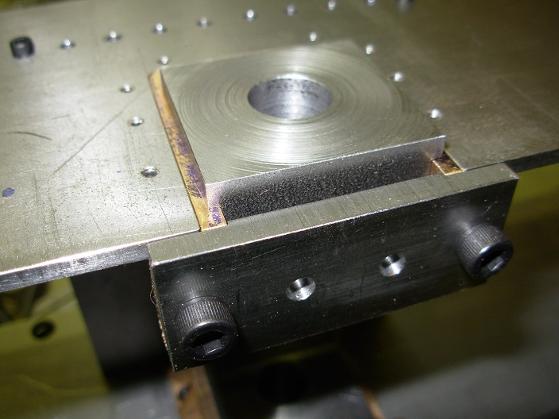

A test shaft was put through each pair of blocks to confirm concentricity and alignmentof the two blocks.

I machined the axle box flange radius using a rotary table. The radius I used was the distance between the axle boxes. This dimension was not on the drawing.