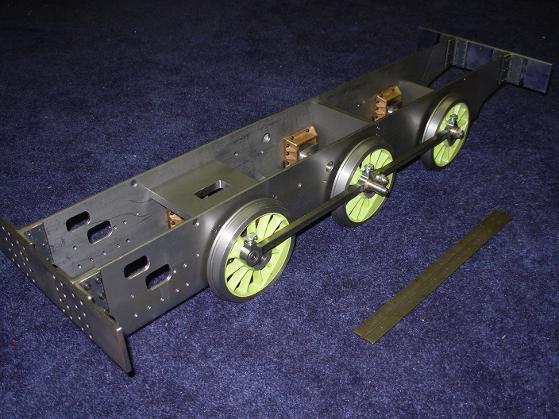

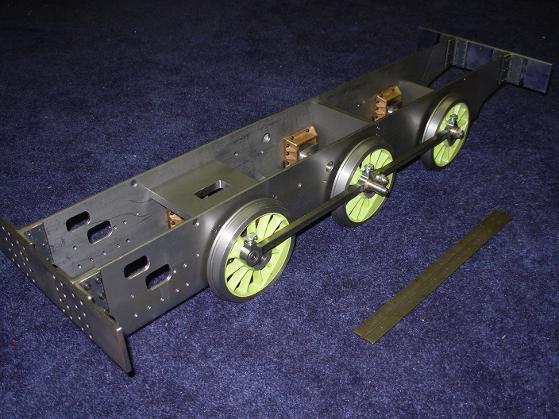

Before making the connecting rods. I made a temporary rod to confirm the center distances of all three axles.

Another temporary rod was made for the other side.

After the crank pin holes were established in the rods, the ends were slotted and finished.

The sides of the rods were machined to size.

The rods in place to check for fit.

Finished rods next to theraw, unmachined, laser cut rod blanks.