Making up the Fittings

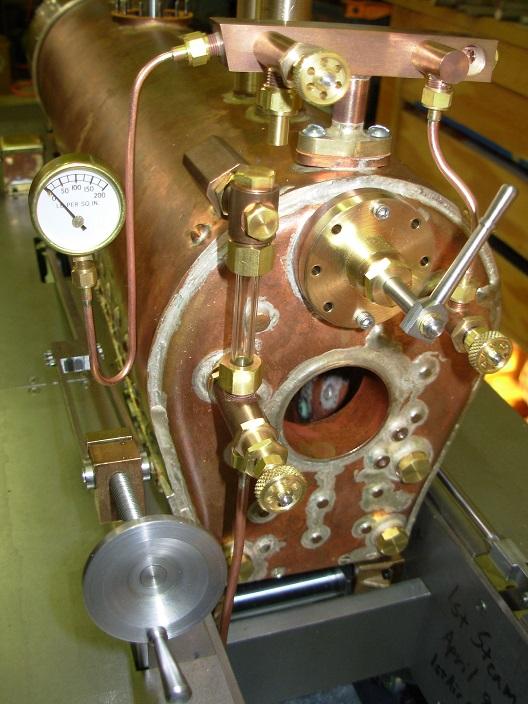

Following, are photos of making the boiler fittings.

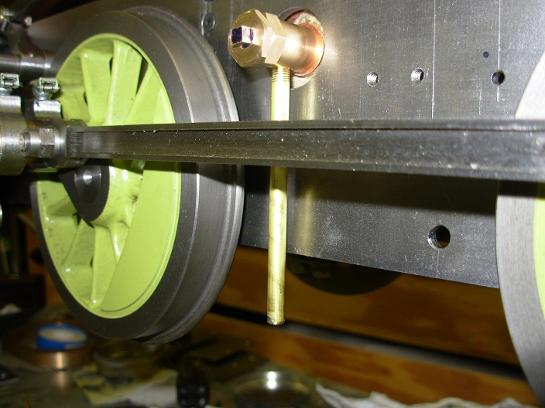

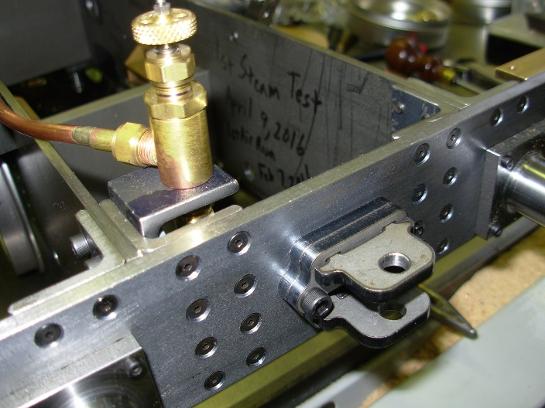

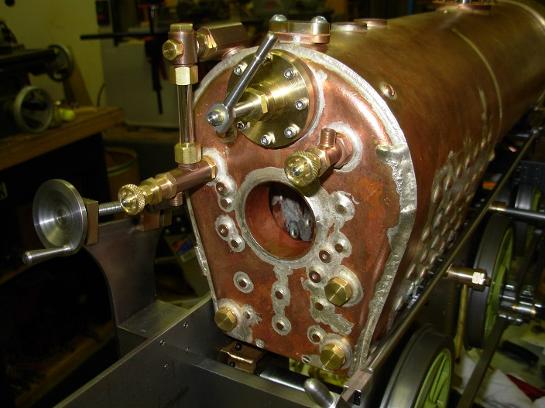

The frames were not opened up for access to the blow down valve until the boiler was fitted to the frames.

Waiting to open up the blow down access hole until after the boiler was fitted, allowed for good alignment of the hole to the valve.

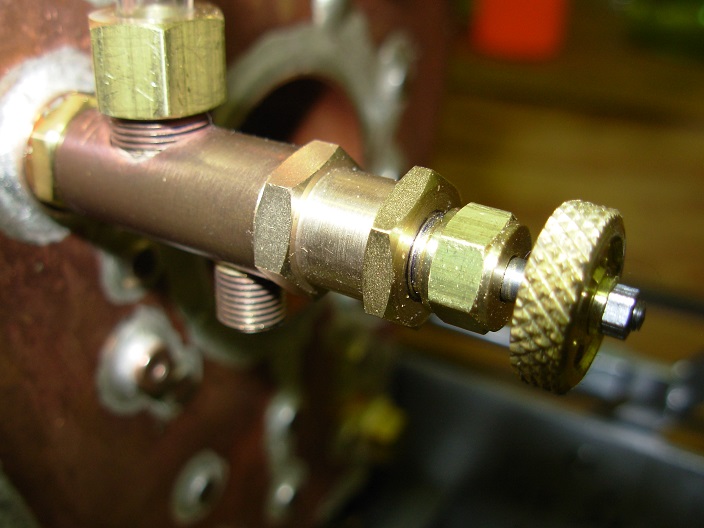

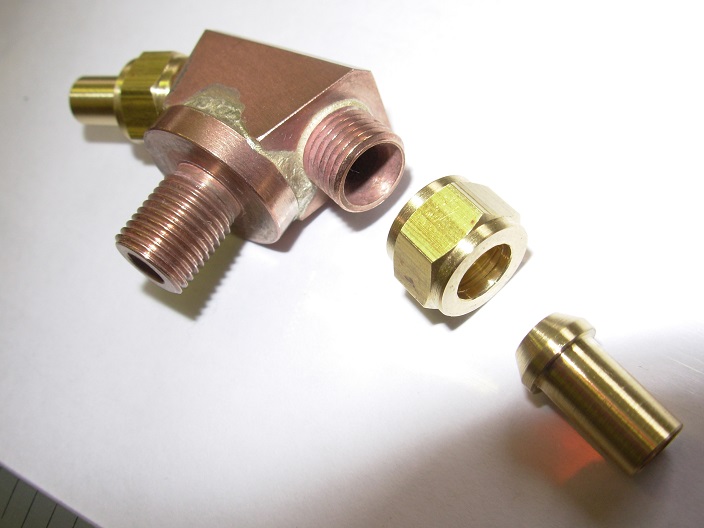

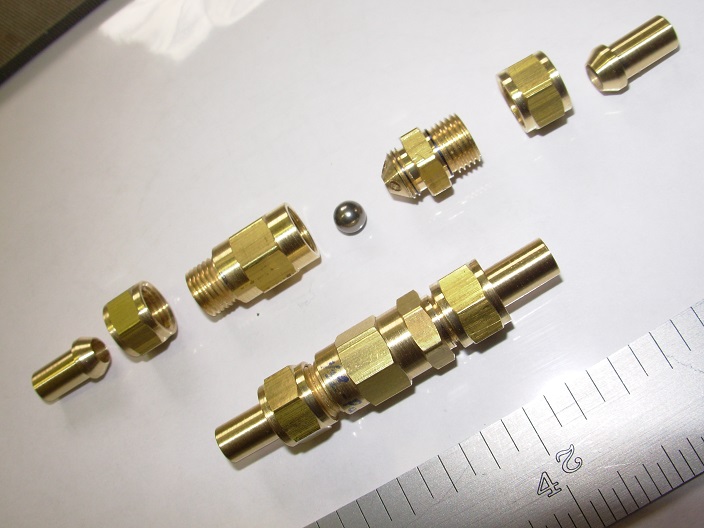

These are the parts that make up the blow down valve. The stem should have been stainless steel.

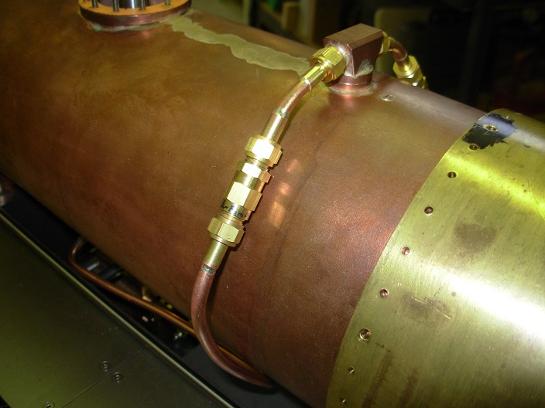

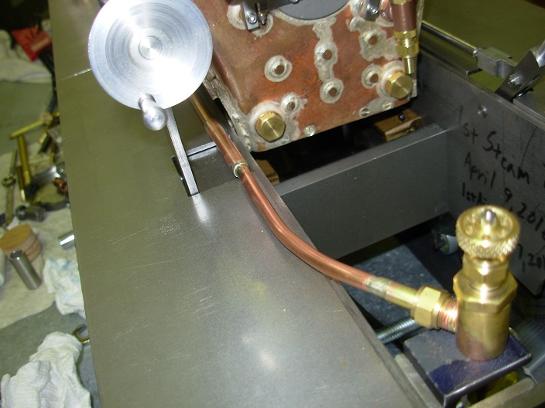

The blow down valve installed and the diverter tube attached.

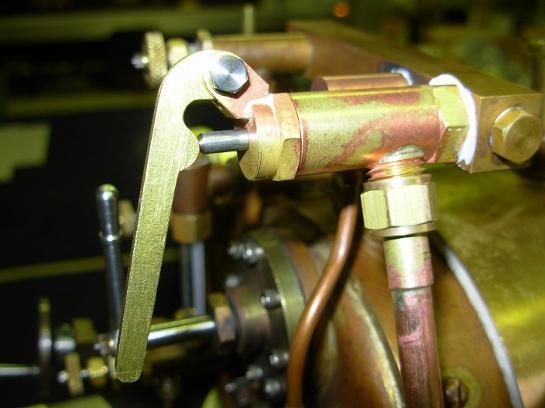

Blower valve.

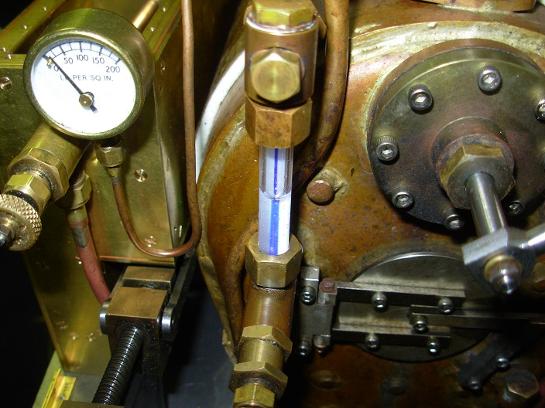

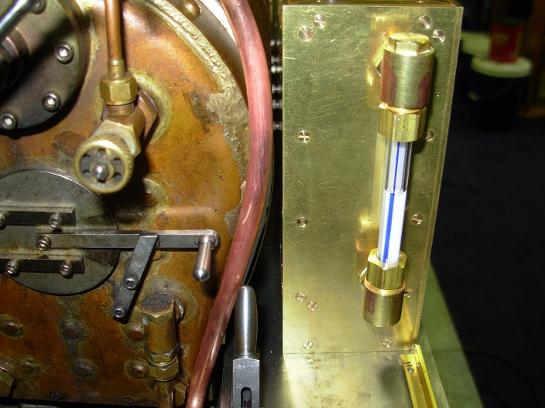

This the bottom fitting for the water glass gauge. It includes the blow down valve.

The parts for the main steam throttle.

This is the dry tube and a driver made for installing it.

These are the parts on the "operator" end of the throttle.

The dry steam tube is covered by the inner steam dome cover.

The safety valves are made to a Gordon Smith print specifically for the Super Simplex.

Another batch of pipe connectors. Many more will be made even after this batch!

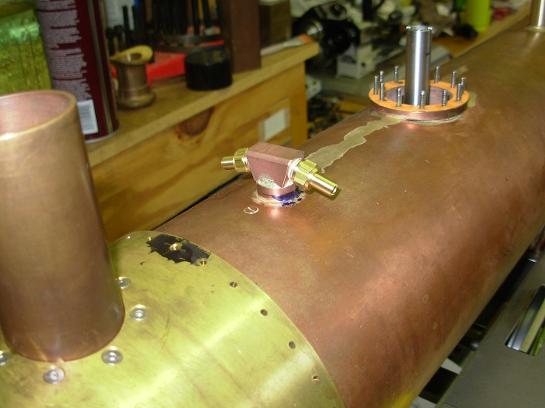

The top feed connector in place.

This is the drilling of one on the inline check valves.

Temporary position of the axle pump by-pass valve.

Piping to the whistle.

The Whistle is mounted under the right hand running board.

The steam pipe to the whistle and the water gauge for the water tanks.

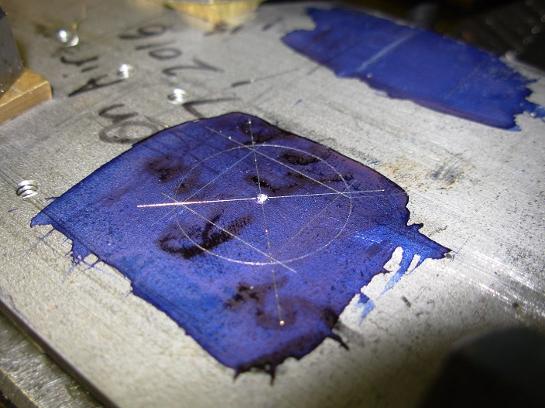

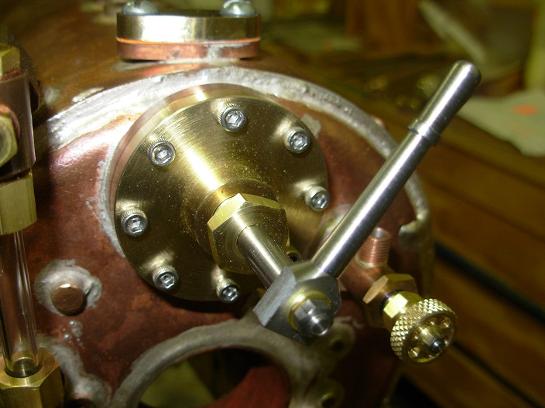

The access hole for the blow down valve is being opened up.

This is a special socket I made for operating the blow down valves.

These are all of the pieces that make up the blower valve. The body is bronze, the spindle stainless steel and the rest brass.

Here's the pieces that make up most of the bottom fitting of the water glass gauge.

The nut is held in the tube by three screws. The nut can be positioned such that the handle of the throttle can be in whatever position is needed.

The dry tube in position off the side of the throttle tube.

The complete throttle tube assembly before installation.

The throttle tube andmain steam valve handle as installed into the boiler.

Fire box door and latch installed.

The fire box door and latch are fastened to the back head with screws that go into the blind threaded bushings.

Boiler top feed connector.

The top feed connector puts water into the boiler from the injector and the axle pump.

The top feed piping has a check valve in each pipe.

Here are all of the parts that go into the check valves.

The pipe from the by-pass valve goes to the boiler top feed.

The whistle was donated by a friend.

The whistle valve is mounted on the steam turret in the cab.