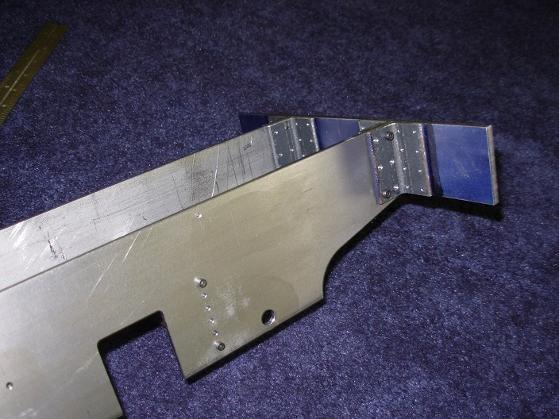

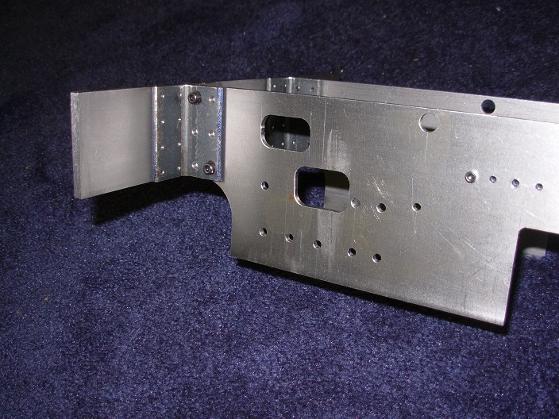

Frames

These are a few photos of the frames. They are not yet completed, and I did not take any early photos of sawing them out, drilling, or machining the openings for the horn blocks.

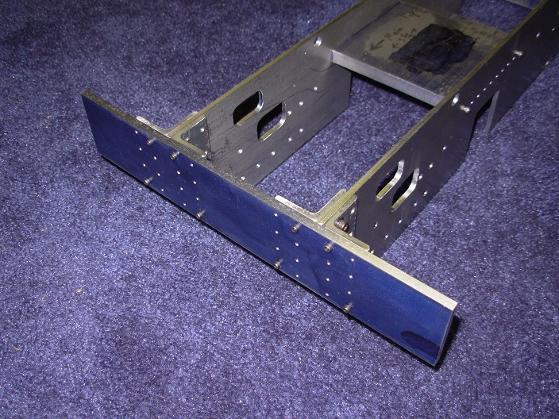

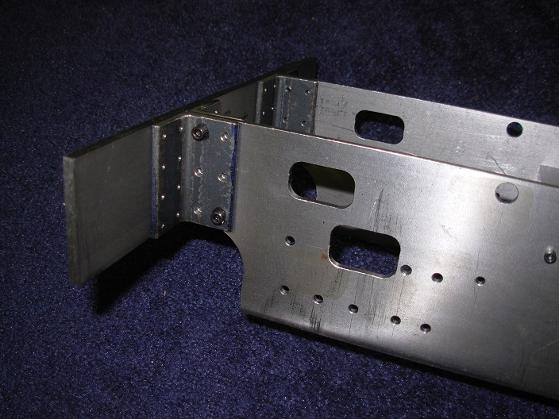

The frames are one of the most important parts of a locomotive. They must be manufactured as straight and square as possible. Each spreader must be a square as is possible and the same distance in width. The frames must lay as flat as possible. If the material for the frames is not flat, it must be adjusted until it is. To a certain degree, the spreaders will pull the frames flat and square, but, they should be as flat as possible to start with.

For re-gauging this locomotive to 4-3/4", it was a matter of making the spreaders 1/4" narrower than called for on the drawing. All of the clearances for standard U.S. 4-3/4" track is maintained with this adjustment.

I left the buffer and drag beams exactly as per the drawing. So, it was a matter of mounting the frames to the beams 1/8" closer to the center. Also, all the plate work from the running boards up, is as per the drawing.