Cab Plate Work & Boiler Jacket

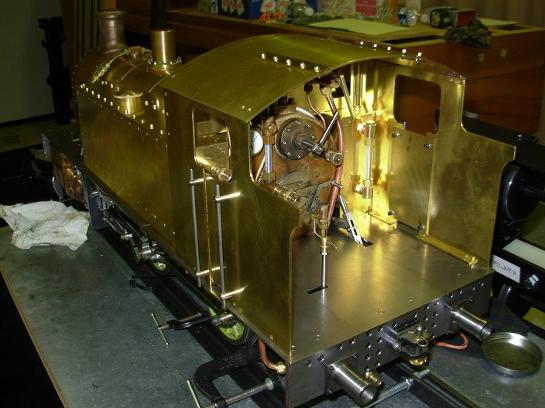

Following, is the construction of the cab and other plate work.

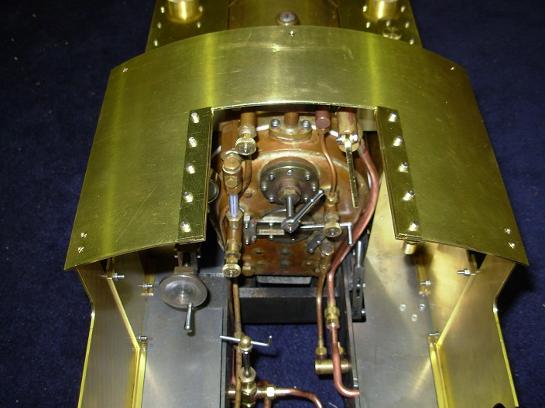

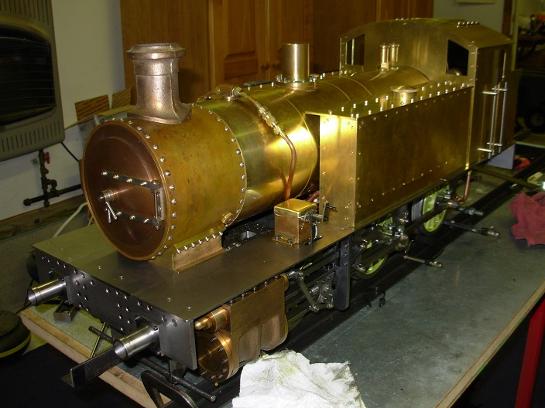

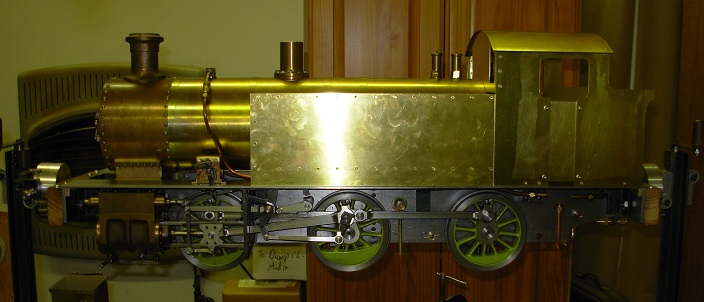

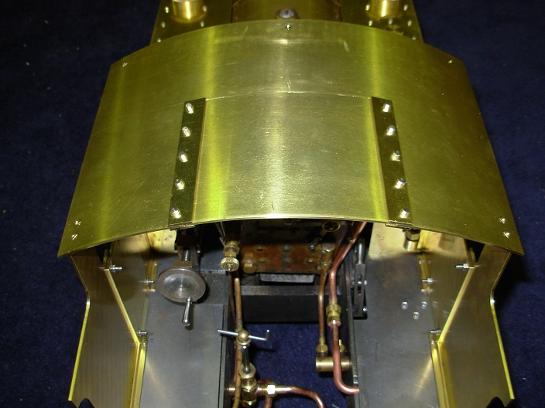

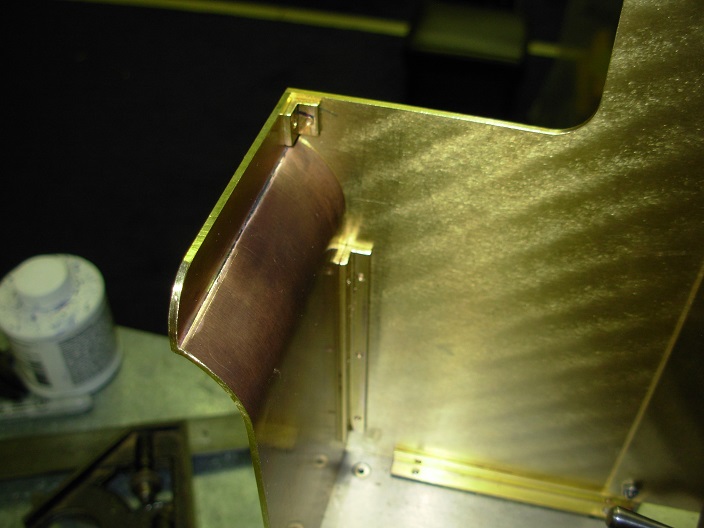

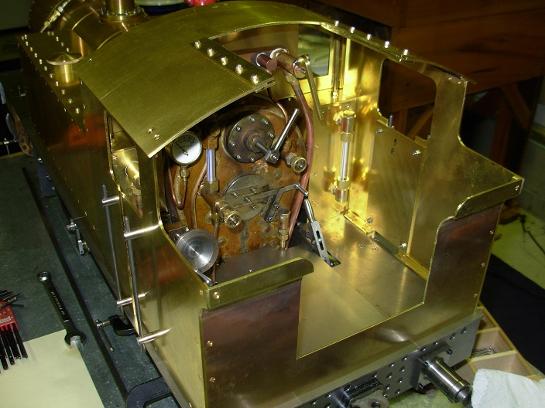

The boiler jacket is made from .020" brass sheet. A little bit of the insulation material can be seen exposed at the fire box. It is 1/8" ceramic wool sheet.

A cardboard template for the jacket was made first and then transferred to the sheet brass.

The tanks are temporarily in position.

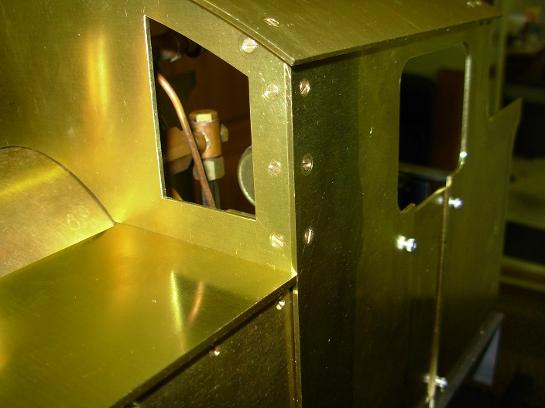

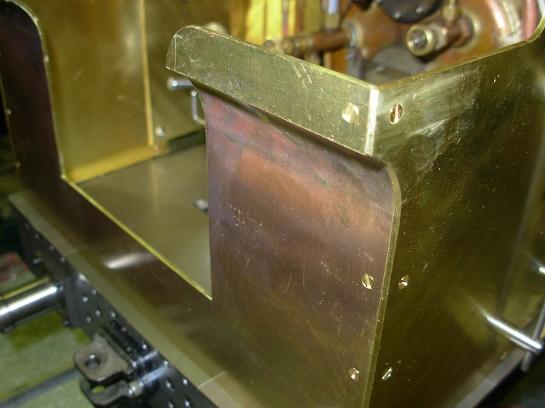

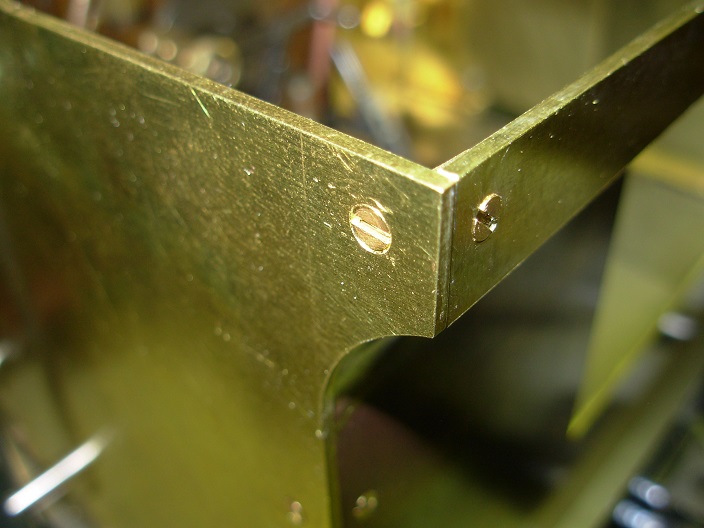

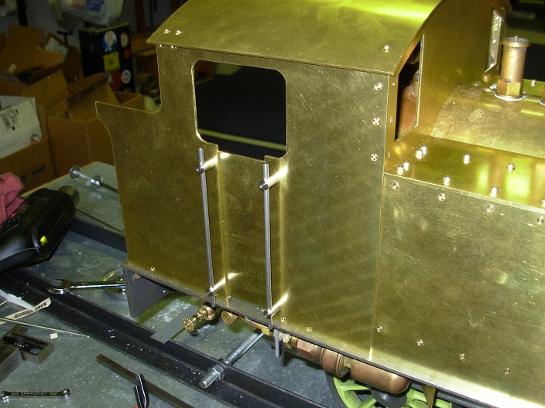

Corner detail of the cab. A change from the drawing was to make the tanks separate from the cab. This is where the joint is.

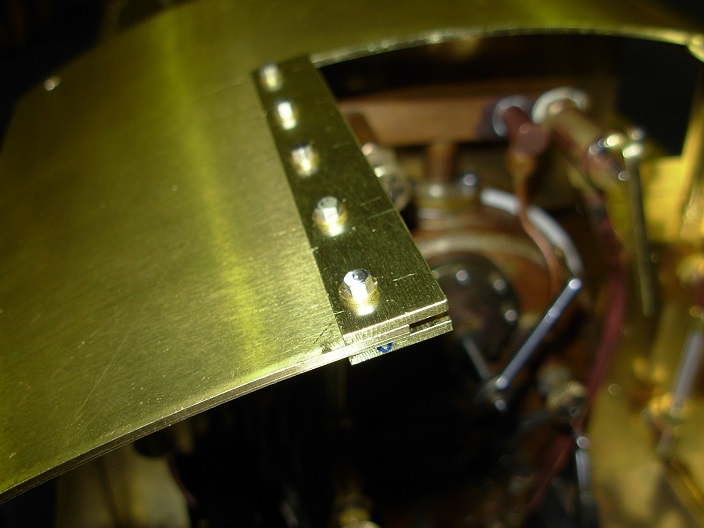

The roof was cut out so the driver can see the controls.

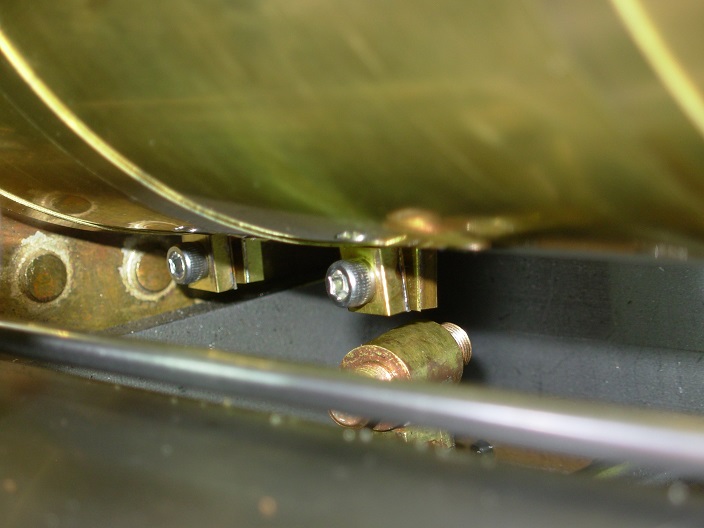

A close up of the roof where the cut-out slides in. This was fastened with miniature hex head screws.

Handrails are installed.

The cab finally gets a floor.

The tank tops have their hex head screws in place.

Detail for the inside of the door.

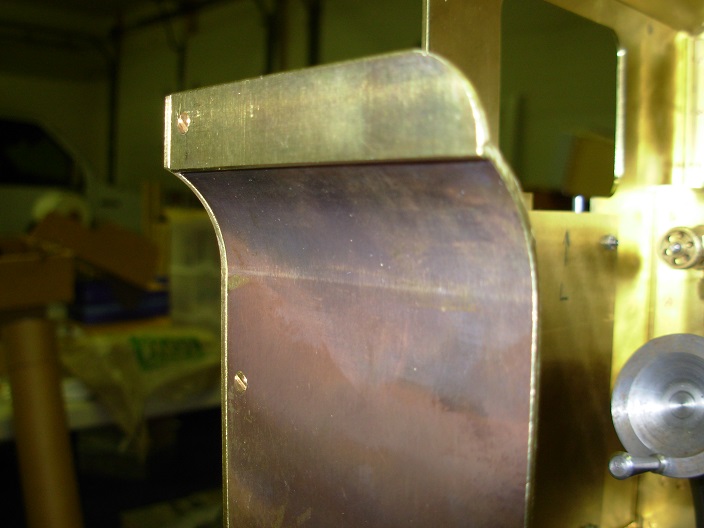

There was no drawing for the cab back. So, this is how I decided to finish it.

The curved back was soft soldered to the short vertical piece on the top. The cut out was done afterward.

Close up of the corner detail of the cab.

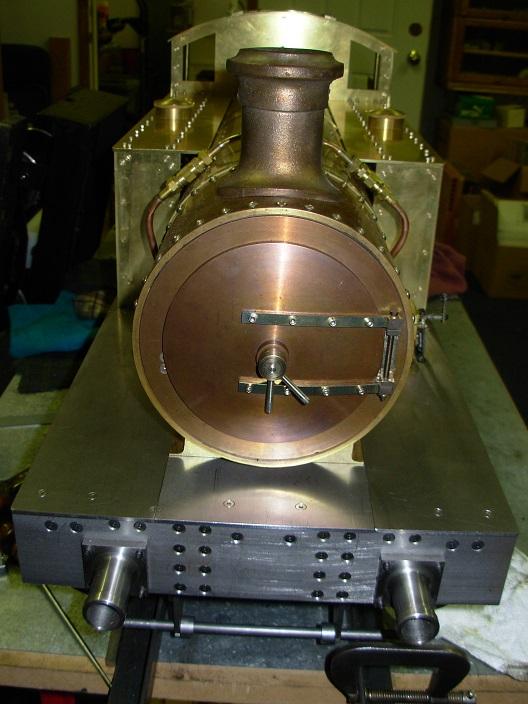

The steam dome was too tall to be mounted vertically. So, it was mounted horizontally.

The inside of the dome was machined so it could be fit tightly on a wooden mandrel.

The smoke stack casting was dealt with in the same manner as the steam dome.

Here's the finished smoke stack and steam dome sitting atop theboiler.

The boiler bands are made from the same material as the jacket. The ends were finished with a square of brass threaded for a screw.

Positioning of the holes was done carefully so no insulation material can be seen.

The fasteners for the tank top are not yet installed.

The cut out section was saved so it can slide into place for a "normal" view of the cab.

The front windows and roof cut-out were all done with a jeweler's saw.

Handrails, simple and effective.

The front of the locomotive also get a running board plate in front of the smoke box.

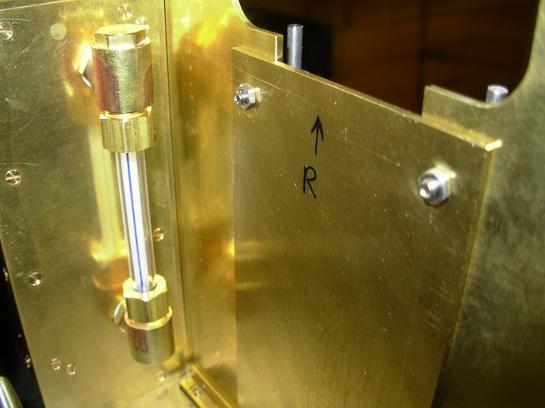

The water tanks have their own gauge glass.

The back of the cab is finished.

The cab back was finished with a cut out that will allow good access for shoveling coal and to be able to clean the fire tubes that are not accessable through the fire box.

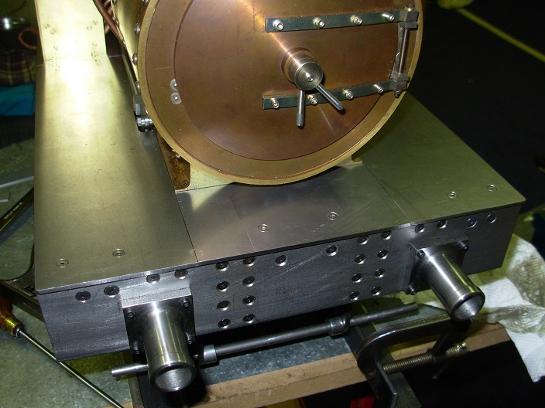

Here's the beginning of a fixture to machine the outer steam dome.

Just like for the cylinders, the lathe is set up like a horizontal boring mill. The radius is the same as the saddle, so, I did not have to move the tool position on the bar.

The casting was mostly cleaned up with files and emery cloth.