Cylinders & Steam Chests

Following, is the cylinders and steam chest construction.

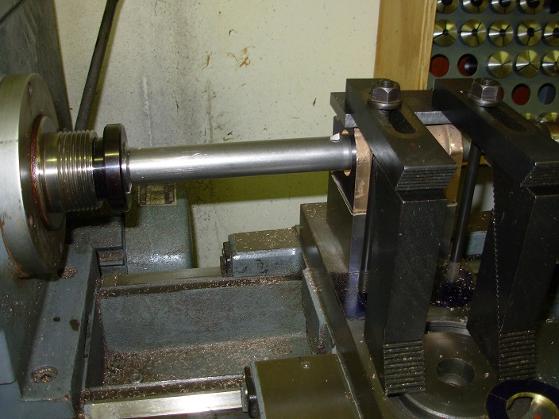

To get a truly parallel bore, a boring bar is turned between centers and the lathe is set up like a horizontal boring mill.

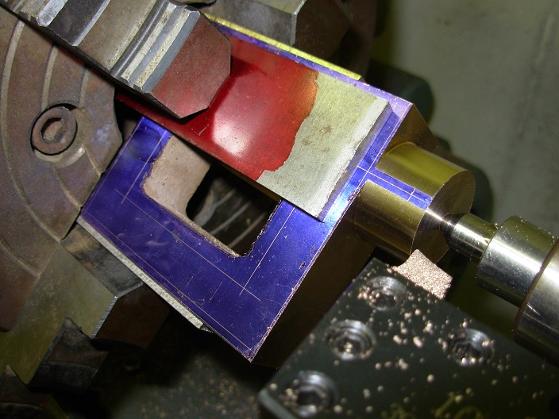

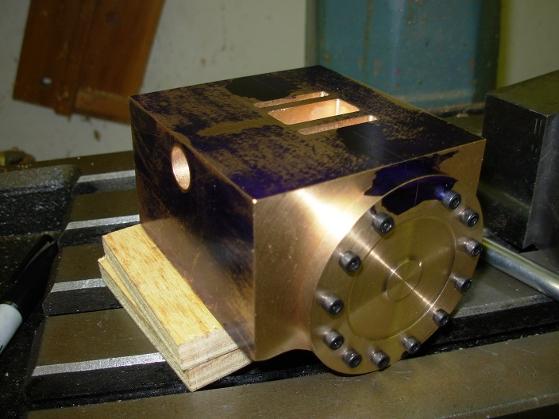

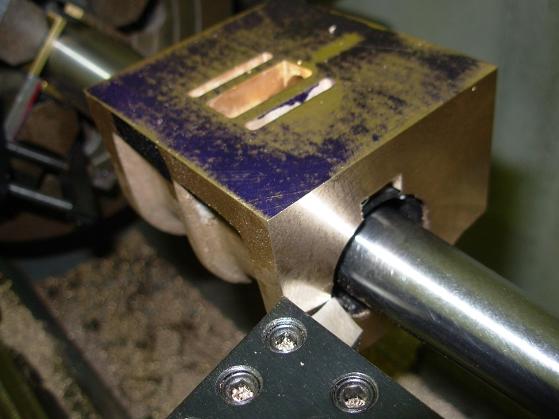

The steam chest took many different set ups in order to bring the casting to size.

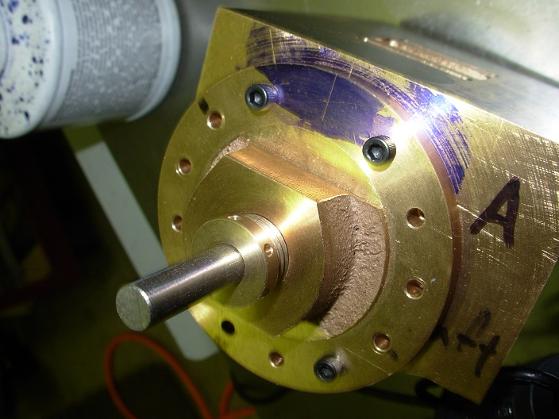

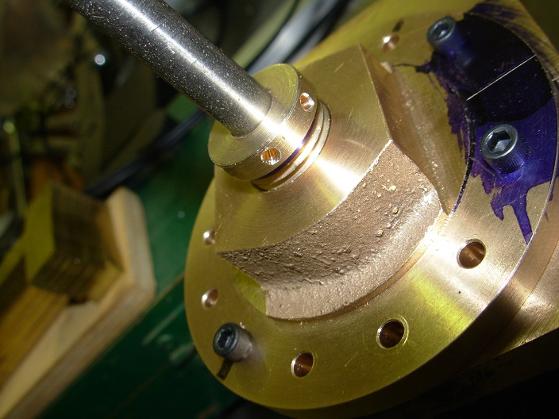

Here, the steam chest is turned between centers.

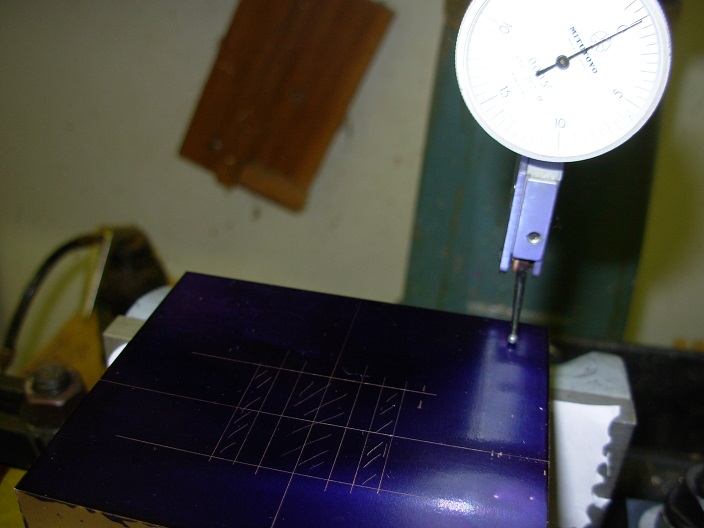

After dialing in the port face of the cylinder, it is ready to machine.

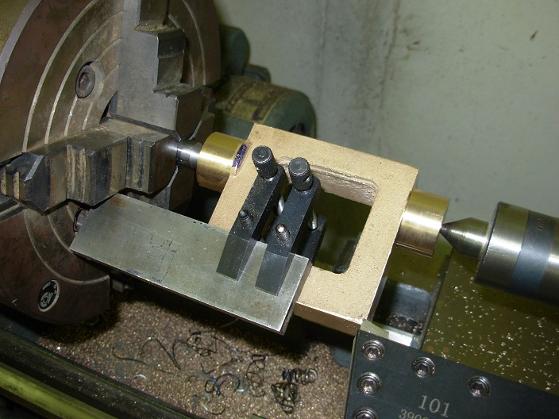

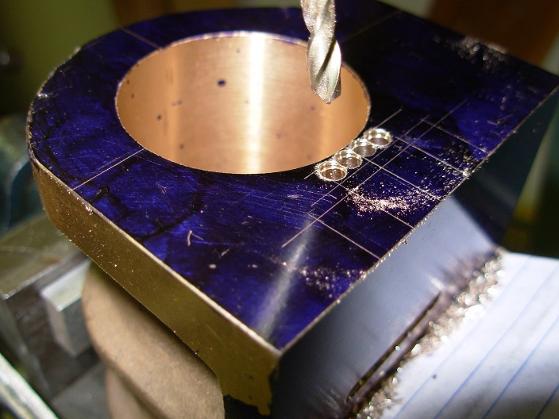

The angle vice is set up for drilling the steam passages that connect the ports to the cylinder ends.

The aft end of the cylinder must be exactly square with the bore.

This is the aft cylinder cover being bored for the piston rod and gland.

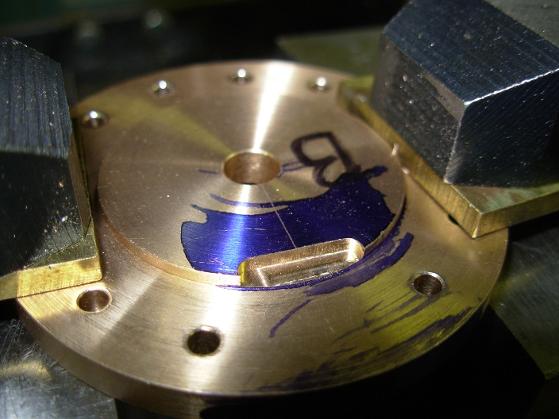

A cylinder cover on the rotary table for drilling the bolt hole pattern.

Forward cylinder cover installed.

The packing nut for the piston rod is drill for a pin wrench.

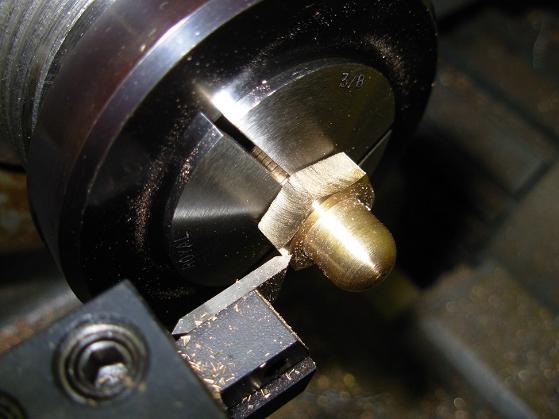

Single point threading the packing nut

The cylinder are drilled for attachment to the frames.

The hex is machined on the nut that will cover the end of the valve spindle.

Finished valve spindle cover nut.

Steam chest in place on top of the cylinder.

I had to drill and tap two holes in the lathe carriage for the clamping studs. The clamps must not be too tight, in order to not distort the casting.

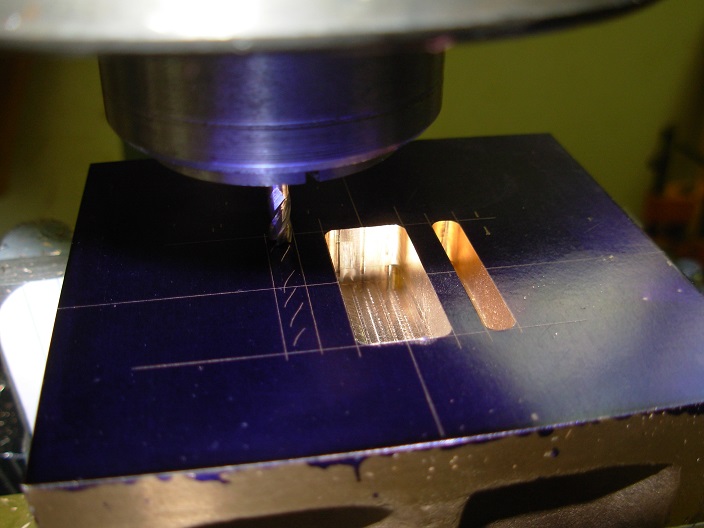

Here, the shaper is used to square up a cylinder block.

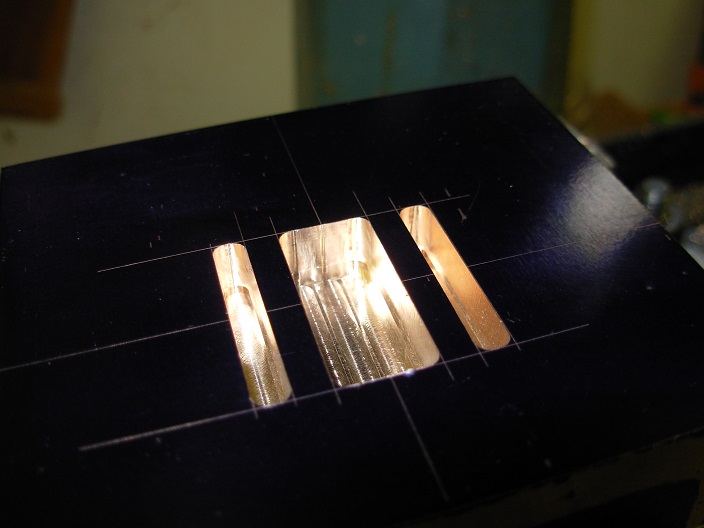

Here, two of the ports are finished.

Four holes were drilled to create the steam passage. These holes were connected with a small round file to create an oblong shaped hole.

The cylinder was mounted on an expanding mandrel between centers, and faced to length.

The flats are being machined for the cross head slide bars.

The bolt hole pattern is slightly irregular due to allowing for the steam passage in the cylinder.

The cylinder covers are relieved at the position where the steam enters the cylinder.

Packing nut for the piston rod in position.

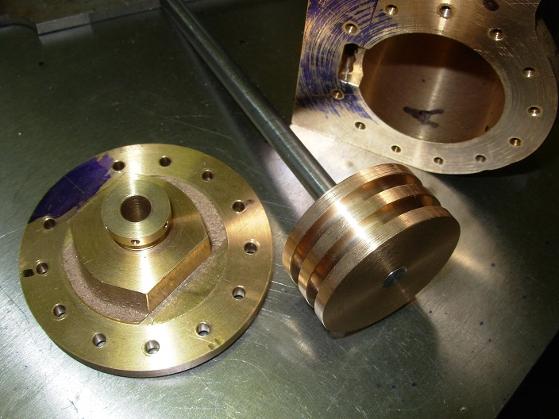

Piston, cylinder cover and cylinder.

Cross head guides are drilled for attachment to the aft cylinder cover.

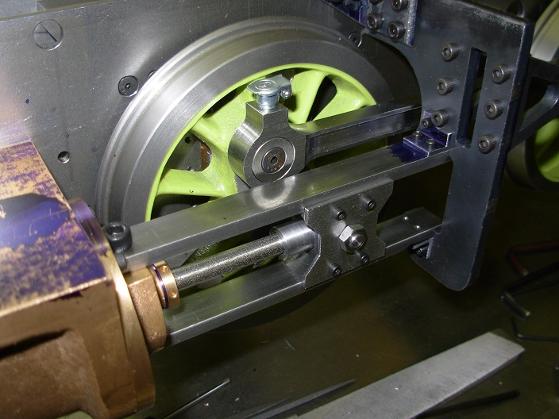

Cylinder, cross head and piston rod all in place.

The hex on the nut is chamfered slightly.