Flanging a Plate

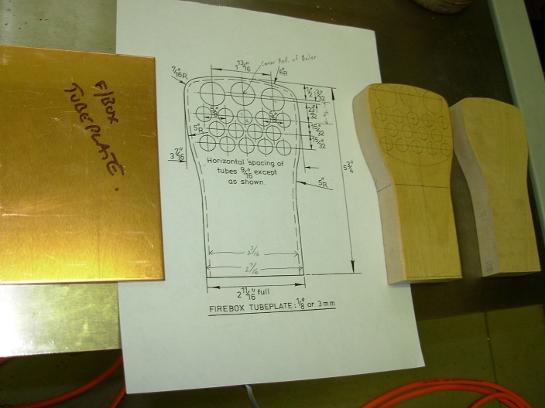

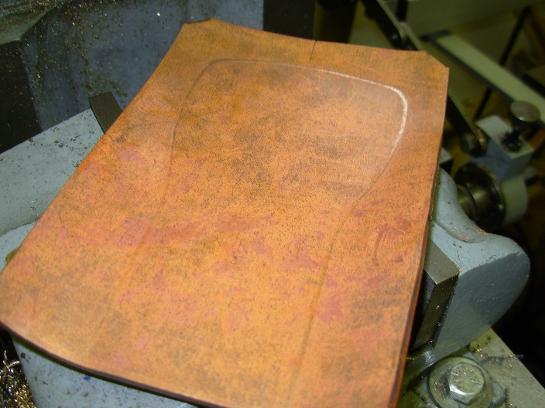

Following, are the steps to flanging a plate. Flanging plates was really a fun process for building the boiler. Annealed copper is like lead and can be shaped almost any way you want, given the right former. The former is made to the dimension of the inside of the plate with a radius on the corner the copper is to go around. The copper plate is positioned between the former and a clamping piece. The clamping piece is just a little smaller than the former so the forming hammer can get around the radius well. The clamping piece also assures that the plate being flanged remains flat. The copper is first annealed by bringing it to a dull red color with a torch. The copper is then clamped between the former and the clamping piece. The edges are beaten with a hard plastic or rawhide mallet. Do not use a metal hammer as it will thin the copper where struck. As the copper is worked with the hammer, it will stiffen as it work hardens. Re-anneal the copper and repeat. The annealing process will have to be done several times before the copper reaches the finished shape.